Hover over the car parts to read more

Scroll below to find out more information

Container ships

Container ships use the NEMO® pump for used oil, oil sludge, oily water and wastewater, the NOTOS® multi screw pump as a hydraulic and windlass pump or for lubricant oil and fuel.

Container ships use the NEMO® pump for used oil, oil sludge, oily water and wastewater, the NOTOS® multi screw pump as a hydraulic and windlass pump or for lubricant oil and fuel.

On oil platform supply ships, the NEMO® pump is predominantly used to convey sludge and drilling chemicals and the NOTOS® multi screw pump for lubricant oil, fuel and cylinder oil, as well as for stripping and heavy oil separation. In addition, the N.Mac® macerator is used for wastewater.

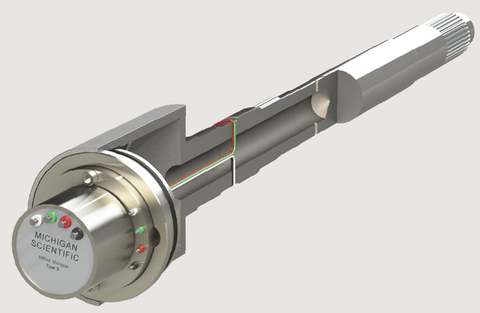

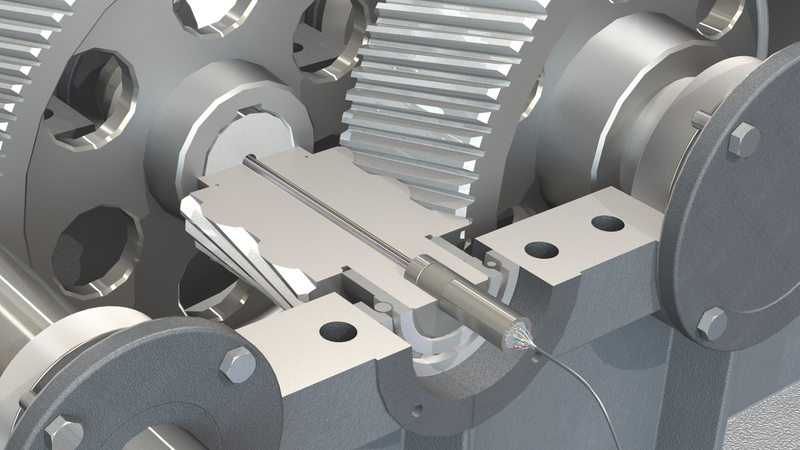

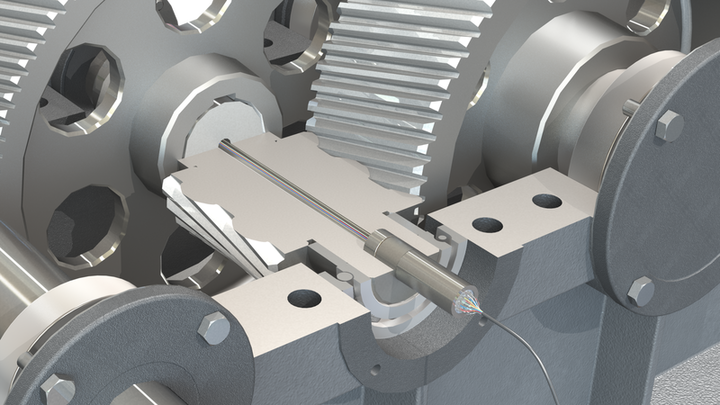

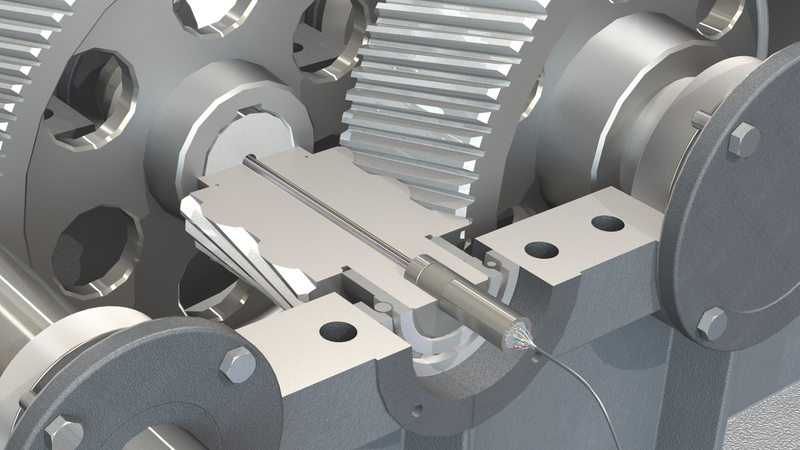

The overall transmission efficiency can be directly measured by applying strain gauges to the driveshaft and transferring the signal using an MSC Tubular Slip Ring Assembly or Wireless Telemetry System. By making measurements in each gear at various speeds, with the converter clutch engaged and releases, and with other variables controlled, the efficiencies of many of the components can be inferred.

Transmission Shaft Instrumentation

On oil tankers, the NEMO® pump is used for residual oil, oil sludge and oily water, the NOTOS® multi screw pump to circulate lubricant oil and the TORNADO® rotary lobe pump to load and unload crude oil.

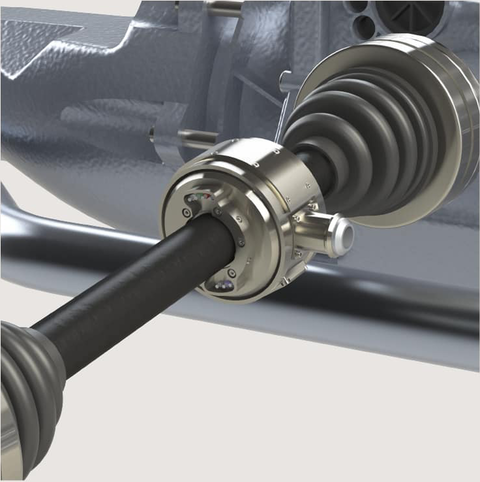

Torque measurements can be made on half-shaft axles for front-wheel-drive or all-wheel-drive vehicles, or on solid axles on trucks. MSC provides Tubular Slip Ring Assemblies and Wireless Telemetry Systems to transfer the signal from the spinning axle to the stationary data acquisition (DAQ) system.

Half-shaft Instrumentation

On passenger ships, the NEMO® pump is used for wastewater, the NOTOS® multi screw pump for lubricant oil and fuel in the engine room and the N.Mac® macerator for grinding and separating large, hard objects in wastewater.

MSC specialises in making strain and temperature measurements on spinning parts, such as on an alternator pulley. Signals from strain gauges and thermocouples are transferred using Slip Ring Assemblies. A low-profile slip ring is ideal so that it does not interfere with other components under the hood.

Alternator Instrumentation

Wharves

On wharves, the media conveyed by the NEMO® pump include highly viscous materials and chemicals. It is also used for stripping tanks and cleaning pipelines, while the TORNADO® pump is responsible for loading and unloading oil and recirculating oil residues.

On wharves, the media conveyed by the NEMO® pump include highly viscous materials and chemicals. It is also used for stripping tanks and cleaning pipelines, while the TORNADO® pump is responsible for loading and unloading oil and recirculating oil residues.

On production and storage units, the NEMO® pump conveys industrial sludge, wastewater and oil-gas mixtures, the TORNADO® rotary lobe pump is used for crude oil and used industrial oil and the NOTOS® multi screw pump for lubricant oil and fuel or for the hydraulic system.

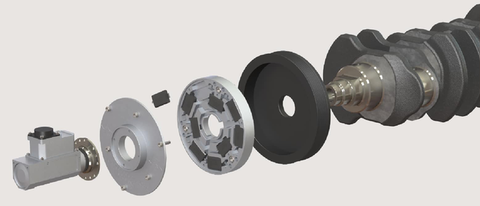

Crankshaft Instrumentation

These measurements are crucial in testing the strength and functionality of an engine’s crankshaft and verifying simulations. With comprehensive expertise in applying strain gauges to production parts, Michigan Scientific can create a custom transducer from a production crankshaft.

Offshore platforms use the NEMO® pump for industrial sludge and oil-gas multiphase mixed chemicals, the NOTOS® multi screw pump for lubricant oil and fuel and the TORNADO® rotary lobe pump for used industrial oil, drill cuttings and drilling sludge.

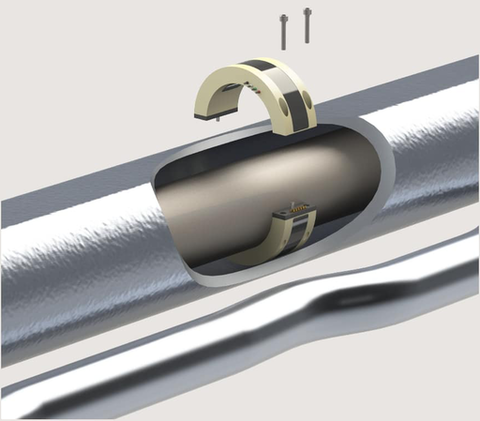

The Split Collar Wireless Telemetry and Induction System is ideal for measuring strain and temperature on shafts in the powertrain. It is a non-contact system that allows the users to remove the system without modifying or disassembling larger shaft ends. The Split Collar Wireless Telemetry and Induction System can be moved and mounted to different shaft of the same diameter or smaller with the use of bushings.

Split Collar Instrumentation

In addition to the transfer of used oil, oily water and wastewater, the NEMO® pump is also used on bulk carriers for stripping, the NOTOS® multi screw pump for hydraulic and lubricant oil and for chemicals as well. The TORNADO® rotary lobe pump can function as a loading and unloading pump for crude oil.

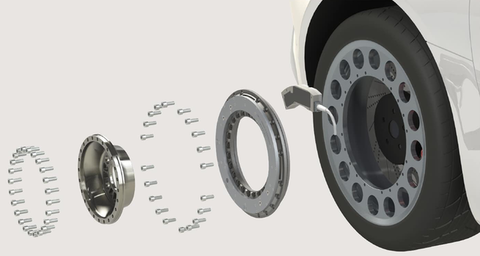

The MSC Wheel Force Transducer is capable of measuring all wheel forces and moments on an array of vehicles. It provides independent output signals for vertical, lateral, and longitudinal forces as well as camber, steer, and torque moments. Being completely weatherproof, it is ideal for on-road and off-road measurements in all conditions. It can also be used to monitor and control laboratory tests.

Wheel Force Instrumentation

As the world looks to cut carbon emissions, policies on fuel consumption continue to get progressively stricter. As a result, vehicle fuel efficiency has made great strides in recent years. A driving force behind this has been efficiency testing. Because testing is so important, having the best tools is essential. Michigan Scientific Corporation (MSC) has over 60 years of experience with providing the equipment and knowledge required for precision testing and instrumentation.

Efficiency in the powertrain plays a key role in maximizing the energy output in vehicles. Measurements taken at the engine, transmission, propshaft, axles, and wheel make it possible to track power losses at each step between the engine and the road. MSC provides the tools and expertise to provide a complete analysis of vehicle efficiency.

The engine includes a wealth of opportunities for analysis, including bending and torsional loads in crankshafts, camshaft loads, and timing and accessory belt pulley torque. MSC can design custom transducers, or instrument production parts to make these measurements possible. MSC’s Flexplate Telemetry Torque Measurement System replaces the production flexplate or flywheel to measure the input power. To measure the output, a driveshaft or propshaft torque transducer can be created by applying strain gauges to the driveshaft and transferring the signal using an MSC Tubular Slip Ring Assembly or Wireless Telemetry System. By making measurements in each gear at various speeds, with the converter clutch engaged and released, and with other variables controlled, the efficiencies of many of the components can be inferred.

As the world looks to cut carbon emissions, policies on fuel consumption continue to get progressively stricter. As a result, vehicle fuel efficiency has made great strides in recent years. A driving force behind this has been efficiency testing. Because testing is so important, having the best tools is essential. Michigan Scientific Corporation (MSC) has over 60 years of experience with providing the equipment and knowledge required for precision testing and instrumentation.

Efficiency in the powertrain plays a key role in maximizing the energy output in vehicles. Measurements taken at the engine, transmission, propshaft, axles, and wheel make it possible to track power losses at each step between the engine and the road. MSC provides the tools and expertise to provide a complete analysis of vehicle efficiency.

The engine includes a wealth of opportunities for analysis, including bending and torsional loads in crankshafts, camshaft loads, and timing and accessory belt pulley torque. MSC can design custom transducers, or instrument production parts to make these measurements possible. MSC’s Flexplate Telemetry Torque Measurement System replaces the production flexplate or flywheel to measure the input power. To measure the output, a driveshaft or propshaft torque transducer can be created by applying strain gauges to the driveshaft and transferring the signal using an MSC Tubular Slip Ring Assembly or Wireless Telemetry System. By making measurements in each gear at various speeds, with the converter clutch engaged and released, and with other variables controlled, the efficiencies of many of the components can be inferred.

As the world looks to cut carbon emissions, policies on fuel consumption continue to get progressively stricter. As a result, vehicle fuel efficiency has made great strides in recent years. A driving force behind this has been efficiency testing. Because testing is so important, having the best tools is essential. Michigan Scientific Corporation (MSC) has over 60 years of experience with providing the equipment and knowledge required for precision testing and instrumentation.

Efficiency in the powertrain plays a key role in maximizing the energy output in vehicles. Measurements taken at the engine, transmission, propshaft, axles, and wheel make it possible to track power losses at each step between the engine and the road. MSC provides the tools and expertise to provide a complete analysis of vehicle efficiency.

The engine includes a wealth of opportunities for analysis, including bending and torsional loads in crankshafts, camshaft loads, and timing and accessory belt pulley torque. MSC can design custom transducers, or instrument production parts to make these measurements possible. MSC’s Flexplate Telemetry Torque Measurement System replaces the production flexplate or flywheel to measure the input power. To measure the output, a driveshaft or propshaft torque transducer can be created by applying strain gauges to the driveshaft and transferring the signal using an MSC Tubular Slip Ring Assembly or Wireless Telemetry System. By making measurements in each gear at various speeds, with the converter clutch engaged and released, and with other variables controlled, the efficiencies of many of the components can be inferred.